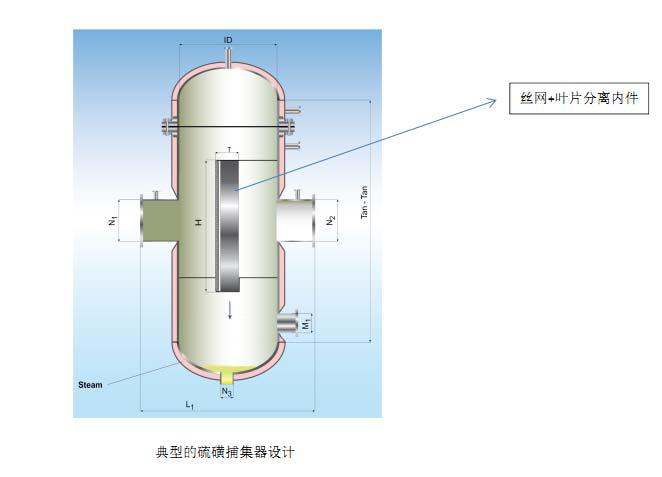

丝网+叶片组合分离

1.丝网+叶片组合分离结构

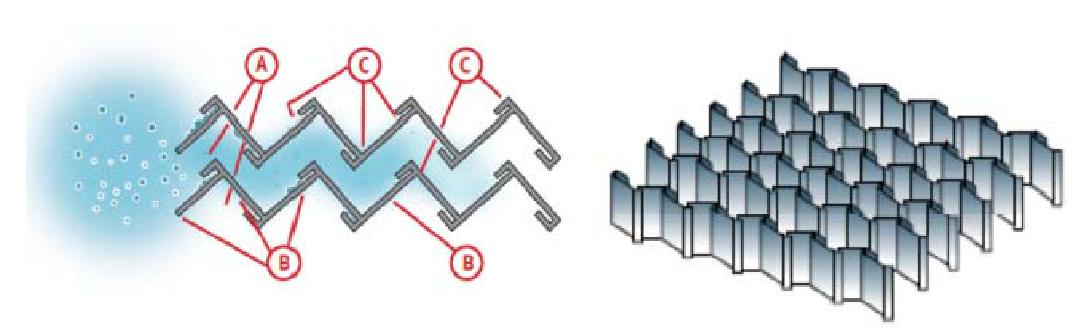

丝网+叶片组合分离在设计开发过程中同时采用动能碰撞、液滴吸附聚结和重力沉降的原理,以实现更高的气液分离效率、更低的压降以及更宽的弹性操作范围。夹带液滴的气体一旦进入分离叶片的通道,将被叶片立即分成多个区域。气体在通过各个区域的过程中将被叶片强制进行多次快速的流向转变。气体在进行多次快速的流向转变过程中,在离心力的作用下,液滴将与叶片进行动能碰撞。液滴之间通过吸附聚结效应附着在叶片表面。附着在叶片表面聚结成膜的液体在自身重力、液体表面张力和气体动能的联合作用下进入叶片的夹层,并在夹层中汇流成股,流入到叶片下方的积液槽中进行收集,得到经过净化处理的气体。

丝网+叶片组合分离可被设计成不同的组合结构形式,以满足工艺性能和容器壳体的外形尺寸要求。组合结构通常包含以下四种基本形式:单组叶片、双组叶片、四组叶片、八组叶片。

| 单叶片 | 双叶片 | 四叶片 | 八叶片 |

1.1 设计特点:

完全固定或可拆的叶片组件;

焊接或螺栓联接的支撑方式;

叶片反冲洗系统;

多级叶片组合系统;

多种形式的气体优化流动分布;

灵活多样的叶片类型。

1.2 工作原理

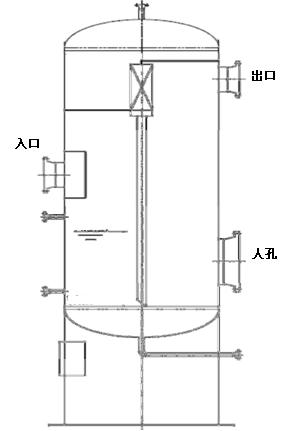

气液两相入口和进料缓冲装置可以帮助减缓气液两相流体进入分离器的动能,同时移除气体中所夹带的大尺寸液滴。气相夹带着剩余的小尺寸液滴进入上方的分离叶片。被分离叶片所捕集的液体在叶片的下方进行收集。收集的液体在自身重力作用下被导液管引入分离器的底部,并最终从分离器的底部被排出。设计合适的液封以防止气体串入导液管,造成流动短路。合理的液位控制以保证底部的液体从分离器中被顺利的排出,同时保证导液管的液封。

优点:

更高的液体分离效率;

更宽的弹性操作范围;

更小的分离器壳体尺寸;

适用于中—高液气比的场合;

适用于存在断塞流的场合;

所有叶片设计基于通过人孔安装,方便对已有的气液分离器进行改造;

分离器入口到出的压降小于 1Kpa

2.高质量效率聚结滤芯精分离器

2.1 工作原理

高质量效率聚结滤芯采用高密度梯度玻璃纤维制造,具有亲水特性,为减少破损漏失设计成整体单片管结构,滤芯表面经疏水、疏油处理,可满足各种精度等级要求。油、水和其他液体的液滴,被聚结器内部的超细纤维捕捉,这些微米级纤维对气流形成了曲折的通道,迫使固体颗粒和液体雾滴在惯性碰撞、扩散拦截和直接拦截三种过滤机理的作用下,被超细纤维捕获,液体表面张力使小液滴聚结成较大型液滴,由于重力作用,大型液滴沉降至容器底部。

当气体进料中同时含有较多液滴和固体微粒时,可以选择离心管束对其进行初级分离。当气体时料中固体微粒含量较小时,可以选择高质量效率叶片对其进行粗分离。在精分离的末端,采用高滤芯,气体从滤芯的内部流到外部,极其微小的液滴和固体微粒在此过程中被捕集,从而实现精分离。液体在聚结滤芯的下方被收集并排出。分离初始压降从入口到出口小于 10kpa,润湿压降为 20~30kpa,推荐更换压降为 70~100k pa。

2.2 优点:

设计灵活,可以满足客户的特殊需要;

分离性能稳定可靠;

可以满足国标对压力容器的要求;

可以满足出中气体中含液量在数个 ppm(质量含量)以内;

筒体法兰设计满足滤芯可拆的要求。

高质量效率叶片式分离器可分离的液体量大,分离精度不如聚结滤芯高;聚结滤芯分离器可处理的液体量相对较小,但分离精度高。在很多应用中,液体的分离量大,且要求分离的精度高,往往采用叶片粗分离和滤芯精分离的两级组合式结构,以达到分离效果。

组合式过滤分离器内件介绍

叶片:分离天然气中的液体

Brief Introduction of Vane Type Liquid/Gas Separator

叶片式气液分离内件简介

1. Vane Type Separation Internal 叶片式分离内件

Vane type separator is a kind of separator special for handling of liquid removal from gas with high efficiency, and little pressure differential, which is the best selection for replacing the traditional mesh pad separator.

叶片式气液分离器是专门用来进行气液分离的一种分离器,具有低压降的特点,是替代传统丝网捕雾器好的选择。

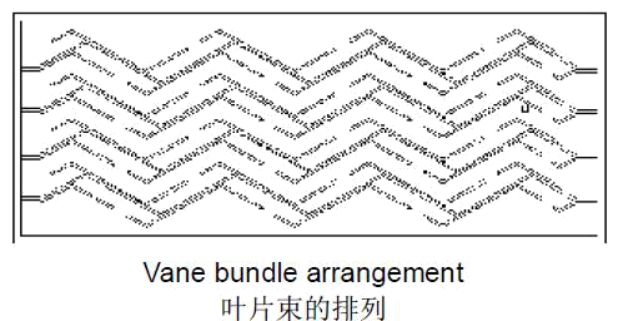

The internal applied is called ‘Vane’, a new type of internal which is widely used in the oil&gas industry, petrochemical industry and chemical industry, etc. after its invention in the 1970’s. Vane is made of papery stainless steel with ‘pocket’ attached, which is patented technology, and is illustrated as bellow picture. When gas and liquid mixture entered the vane bundle, the feed gas will change its direction and do ‘Zig-Zag’

movement in the special arranged vane bundle space, then the liquid will drop down along the wall of the vane, and gas go forward to the outlet of the vessel. Beside the ‘Zig-Zag’ movement, the pocket of the vane will help to change the direction of feed gas, where there will be vortex occur, then, fine liquid droplets will encounter the pocket wall and grow to bigger ones, separated from the gas. Meanwhile, because of liquid vortex, there will be a low pressure area occur in the pocket area, where large quantity of separated liquid will be absorbed here and gathers then go down long the pocket wall, hence the liquid handling capacity is outstandingly enhanced. Because the internal is made of stainless steel, which is robust, and the space between vane and vane is large enough for the preventing of blocking compared to the traditional ones, so there is no need to replace the internal in the separator’s life time.

叶片式分离器采用成为‘叶片’的分离元件,这种分离元件是一种新型分离内件,自从 19 世纪 70 年代问世以来,广泛的应用于石油天然气行业、石化行业、化学行业等工业领域。叶片由非常薄的不锈钢片,利用专利技术制造而成,折叠形的钢片上带有“兜”状突起(如下图所示)。当气液混合物进入叶片束后,会在特殊排列的叶片束空间内做改变方向的曲折运动,于是液体就会分离出来顺着叶片壁滑落至底部。与此同时,当气体遇到叶片的兜状突起时,气体会在兜状物的空间内产生漩流,进而使得微小液滴撞击兜状物的壁而聚结在一起,进而与气体分离。由于旋流的发生,兜状物空间内会形成低压空间区域,由于吸附作用,大量的液体会聚集在此区域,并滑落下去,因此叶片式分离器的处理气体中液体夹带量的能力显著增加。因为是由不锈钢片制作而成,并且相对于传统的气液分离器内件,叶片组件之间的空间足够大,不会发生堵塞现象,因此叶片式分离器使用寿命期间不需要更换内件。

With its excellent performance of liquid separation from gas, vane is world widely accepted as a revolution of internal idea for liquid removal from gas. Today, vane type separator is appointed by many world famous oil companies and processing package providers such as Shell, BP, ChevronTexaco Corp. and UOP, as qualified liquid/gas separator and applied with large quantity.

由于具有完美的从气体中分离液体的能力,今天叶片式分离器已经被闻名的油气巨头或者著名的工艺包供应商,比如壳牌,BP、雪佛龙德士古、UOP 等指定为合格的气液分离器并大量采用。

2. Vane Type Inlet Device 叶片式进口设备

Vane type inlet device is Shell patented product invented for the pre-treating of the feed gas. One function is to pre-separate large liquid droplets from gas when there is large quantity of liquid entrained in the feed gas, and the other one is to distribute the feed gas to the internal evenly. These two functions are both aim to guarantee the performance of the separator. The right picture shows the Shell called‘Schoepentoeter’ which is often applied when there is big content of liquid in the gas.

叶片式进口设备是壳牌的专利产品,这种进口设备具有两种功能,首先,在来料气中含有大量的液体时,可以预分离气体中的大的液滴,第二,可以保证气体均匀的进入分离器内件。这两种功能均为了保证分离器的分离效果。下图中即为被壳牌石油公司称作 Schoepentoeter的叶片进口装置

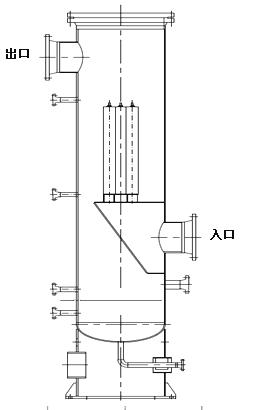

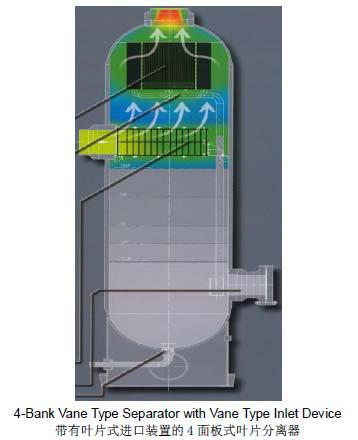

4. 4-bank Vane Type Separator with Vane Type Inlet Device 带有叶片式进口装置的四面板式叶片分离器

Normally, when the liquid content in the feed gas is larger than 15% (Weight Ratio), a vane type inlet device is required to pre-separate the larger liquid droplets from the feed gas in order to guarantee the performance of the whole separator. The bellow picture shows a typical vane separator with capacity of handling large feed gas volume with much liquid content. A vane type inlet device and 4-bank vane bundle are configured and liquid downcomer pipes are included as well to avoid liquid coming down encounters with the feed in gas leading to second time entrainment.

通常情况下,如果进料气中的液体含量超过 15%(重量比),需要在进气口安装叶片式进口设备预分离来料气中的大液滴以保证整个分离器的分离精度及分离效率。下图所示为典型的处理大气体量且带有大量液体的叶片式分离器(带有进口预分离装置),这种叶片式分离器的叶片配置为 4 面板形式,进口带有叶片式预分离装置,并且带有降液管,目的是为了使分离出的液体直接流入容器的底部,不会在下降的过程中与来料气再次接触而形成二次夹带而降低分离效果。

5. Vane Type Separator Performance Guarantee 叶片分离器的性能保证

①100% removal of liquid droplets from gas 8 μand larger; 99.95% removal of liquid droplets from gas 6 μand larger; 99.5% removal of liquid droplets from gas 5μand larger; 100%去除 8 微米及以上的液滴;99.95%去除 6 微米及以上液滴;99.5%去除 3 微米及以上的液滴; ② Less than 1/10 US gallon liquid entrainment per 10^6 feet^3 outlet gas (0.0137ppmv);

出口气体中每百万立方英尺气体中液体含量少于 0.1 美国加仑(0.0137ppmv); ③Pressure differential is less than 1.5 psi Flange to

Flange (on condition of the inlet and outlet nozzle IDs are properlydesigned). 在正确的管口内径设计的情况下,整个分离器(法兰-法兰)的压降小于 1.5 psi (约为 10kPa)。 ④No need to replace the vaneinternal through the whole design life time of the vessel. 压力容器设计寿命内,叶片内件无需更换。

6. Vane Internal Photo 叶片内件实物图(单件)

分离内件丝网